ENGINEERING

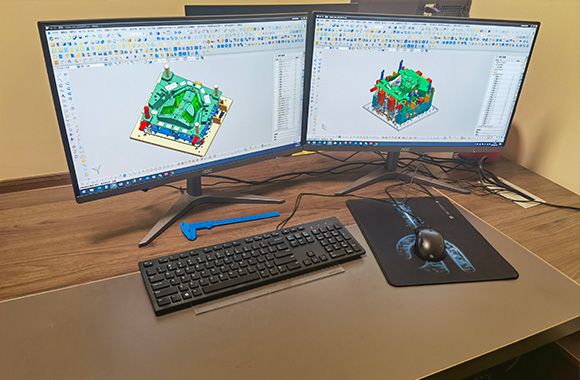

At HongTu we work with customers no matter if they have complete part design or just preliminary ideas. We offer our customers a specialized and rigorous team equipped with proper software, study and make detailed analysis to assist them in developing their part design and making important decisions.

Design Engineering Capabilities:

- DFM & Mold Flow

- Mold Design

- Design Validation

- Tolerance Analysis & Steel safety

- Steel Ordering

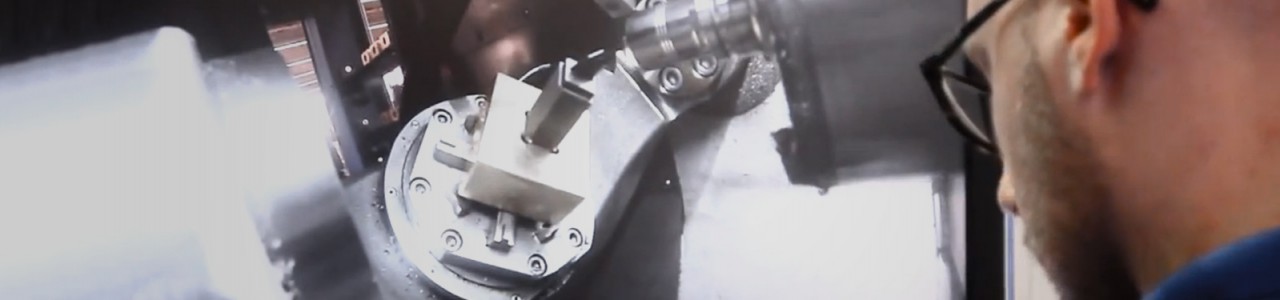

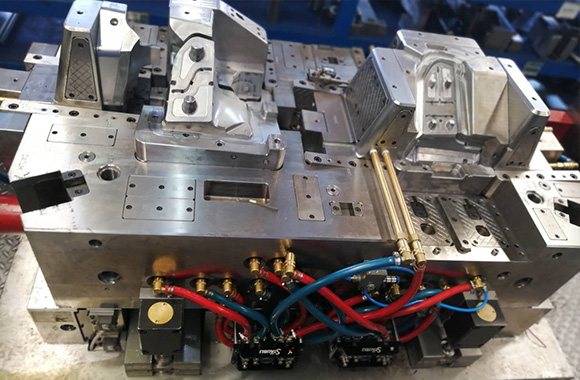

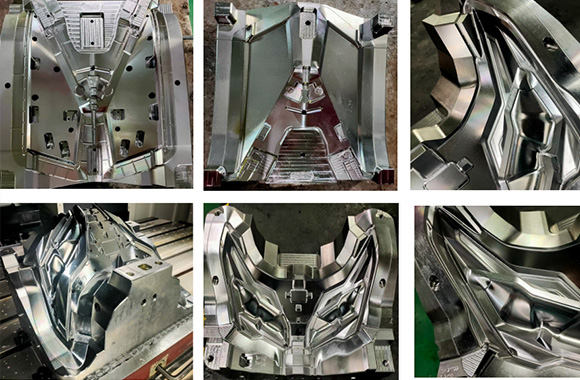

INJECTION MOLDS

HongTu Mold is specialized in manufacturing and maintenance of small to medium sized molds (up to 30T). A team of highly trained professionals, with expertise and know-how, is accomplishing challenging and demanding projects every day. With over 20 years of experience in mold making, high quality standards, and the aim of continuously improvement, assure a reliable long term partnership with all our customers.

Mold Making Capabilities:

- Injection Molds

- 2 Shots Molds

- Over Molds

- Insert Molds

- Prototype Molds

- Precision Molds

- Multi-cavity Molds

- Stack Molds

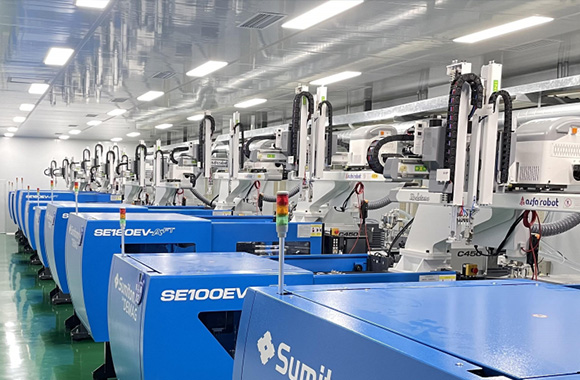

INJECTION MOLDING

With 25 injection molding machines ranging from 60 up to 650 Tons, HongTu offers its partners injection molding service. No matter high volume or low volume production, we offer outstanding engineering, quick turnaround, quality and cost-effective services.

Moreover, we have the capability of 2 shots molding, over molding and insert molding.

Resin:

PP, PC, ABS, Nylon, Glass-filled Nylon, TPE, TPU, HDPE, PVC, and etc..

PRECISION COMPONENTS

To satisfy more and more customers’ needs, HongTu also provide precision components manufacturing for customers, like inserts, sliders, cavity blocks, mold base and etc.

Our wide varieties of products are determined by our ability to maximize your success – and we know for injection molded plastics, the engineering and design development process is critical to achieving your target!

We have found the two most critical factors for success in the engineering and design development process are partnering with you early on in the design phase – and focusing on what we consider the 5 Keys To Success for engineering out cost and engineering in quality and optimal performance. In order to achieve success, all 5 of these stages must work together.

- Part design-understanding the product application, intended market and performance, end use objectives and use environment

- Mold design&build-design for mold efficiency, longevity and performance

- Molding process- injection molding technologies, cycle times, material flow and employ scientific injection molding

- Quality- assurance- focusing on tolerance, part inspection, steel safe mold and more

- Automation, in the injection molding process and downstream- making it simple and lean

Our experience , along with the latest innovations in custom plastic injection molding technologies, has provided us with a competitive advantage on each and every project!

Multi-shot Injection Molding

HongTu Mold specializes in multi-shot injection molding as well as 2-shot plastic injection molding.

Plastic Over-Molding

HongTu Mold has many experiences in custom plastic overmolding!

Insert Molding

HongTu Mold has many years of experience as a custom plastic insert mold